From the Heart of the Outback | 1995

1995 was an interesting year - our name was Wool Wares and we had our own brand called Ewe Two. It was also a year of one of the worse droughts on record in Queensland and so much time was spent keeping stock alive with the added emotional and financial stresses that a natural disaster brings with it. More than ever an off-farm income was important at this time.

Smoko Time (morning or afternoon) tea while mustering. Mustering was usually an all day job starting well before dawn and finishing late in the afternoon. Kerrie and her parents Sandra & Neil Richards. Clareborough Station, Richmond, Queensland. 1995

This was the year that Kerrie started research & development of her own 100% Merino jersey fabric. A textile chemist from Melbourne, Dougal Pleasance, mentored Kerrie Richards and helped her navigate the complex world of processing raw wool through to fabric. This combined with her in-depth knowledge of the raw product, helped her to develop Merino Country's own user-friendly, lightweight, soft easy-care, 100% Merino Jersey for every day wear. This is what sets the quality of our products apart even today!

In those days we didn't have Internet or mobile phones or social media! We were still on a "Party Line" with 5 other properties. A party line was a telephone line shared by more than one user with . It was not uncommon to pick up a telephone receiver and hear a conversation already occurring. The town's news often traveled this way despite party line etiquette which dictated never listening in on another's conversation - Our phone number was 36N, one long ring followed by one short ring. When we got a Radio Digital Satellite tower it really changed the game for us... we got a "proper" phone number, 077 418 535 and a Facsimilie (Fax) machine, 077 418611

One of our first swing tags with the contact details of Clareborough Station. While bringing some sheep in for shearing Kerrie saw a ewe standing under a windmill in the distance, silhouetted against a setting sun with these vivid outback colours!

Shearing is one of the busiest times of the year with all hands on deck and long days working in extreme conditions. It's also a very social time of the year with the whole shearing team staying on farm at Clareborough Station which is 60km from Richmond in North West Queensland, working and eating together for up to 2 or 3 weeks.

Team work is essential with the family usually mustering (bringing the sheep into the yards) and drafting (putting the sheep in mobs to be shorn) and once they've been shorn treating the sheep for any animal husbandry issues before taking them back to the paddock.

Shearing is similiar to having a hair cut but with whole team to keep things moving smoothingly including

The Penner Up (often a The Shed hand or Presser): responsible for keeping the pens inside the shearing shed full of sheep, moving them from outside yards into the shearing shed into a pen ready for the shearers.

The Shearers: take a sheep from their pen and position them comfortably on their back. Most shearers can take roughly 3-4 minutes per sheep, working through about 140 sheep each per day.

Wool Handlers or Roust Abouts: As soon as the fleece has been shorn, the woolhandler gathers up the fleece and throws it across a large table. The woolhandlers skirt the fleece. Skirting removes the lower-quality edges of the fleece, which are kept separate from the main fleece wool. This can include necks and pieces, and soiled wool. The remaining fleece is rolled and given to the wool classer

The Wool Classer: The wool classer sorts the wool into five main categories — fleeces, necks, pieces, bellies and locks. Fleeces are also sorted into lines (groups) according to their micron count (fineness of the fibre)

Presser - Once classed the wool is pressed into wool packs and become a bale of wool. All the bales are sealed and marked with a brand that identifies the woolgrower, the classer and the type (breed and category) and quality of wool inside.

When shearing is over and all the wool has been pressed into bales it is then loaded onto trucks and transported off to a wool store in the city ready to be sold at a wool sale.

A local shearing team getting the wool off the sheep in the shed whilst the family usually do the work outside the shed including mustering, drafting and animal husbandry. Shearing Time at Clareborough Station, August 1995.

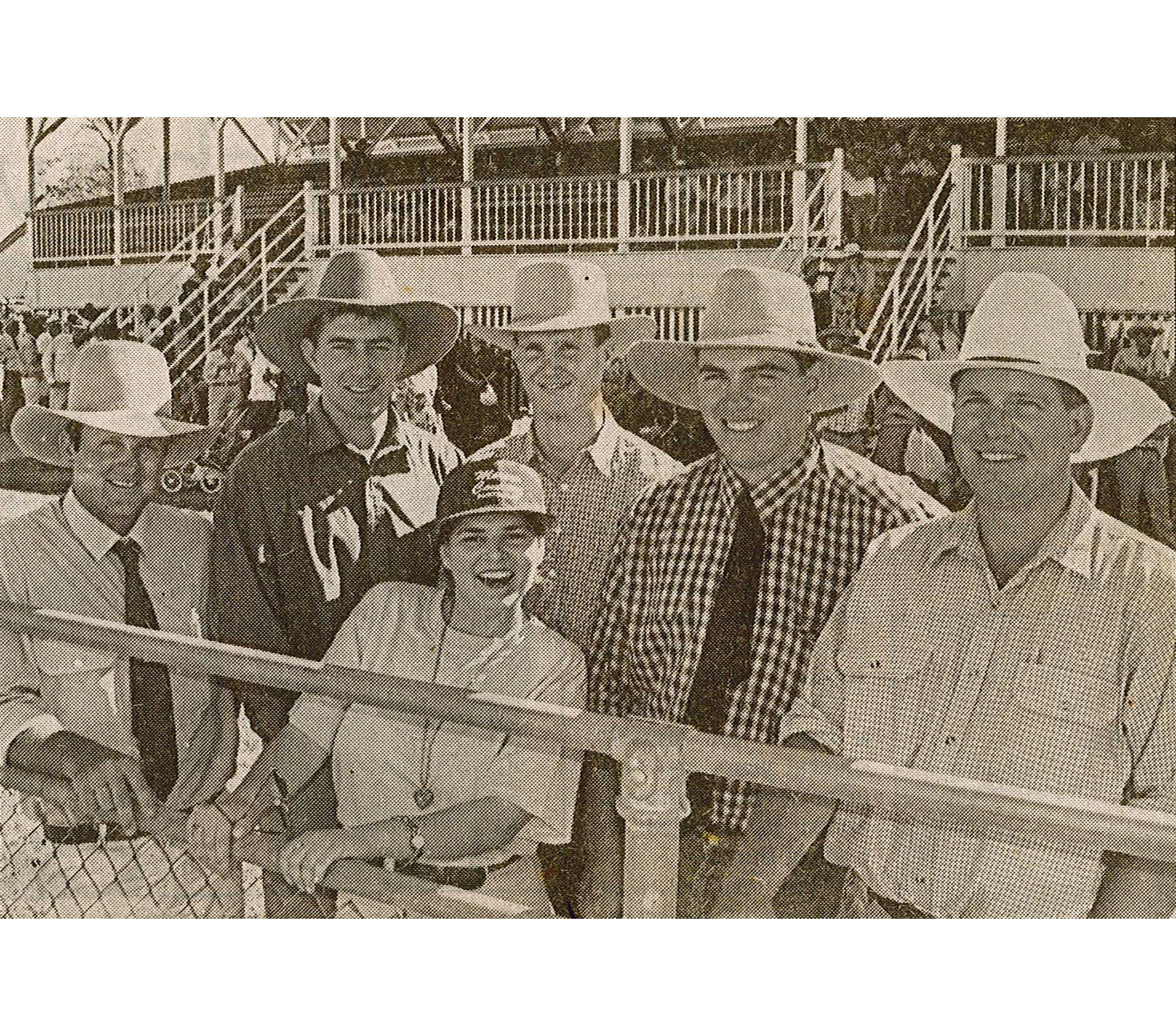

Kerrie with her brother, Glen at the Waltzing Matilda Centenary, Winton. 1995

In 1995 we exhibited at the Waltzing Matilda Centenary in Winton celebrating this iconic Australian song and all things from Outback Queensland! It was at the Centenary celebration that the Minister for Rural Communities saw Kerrie's Merino business and asked how he could help small businesses in the bush - with no mobile phones, social media and being so far west, she told him that these businesses needed customers in the City and plans were put in place to exhibit at the opening of the new Brisbane Convention Centre with a section called Rural Queensland on Show. This was when journalist, Kenrick Riley penned the term from PADDOCK TO PADDINGTON about Kerrie and Merino Country coming to Brisbane City from Outback Queensland!

Read Our Newspaper and Media Clippings From 1995

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.